Design Guidelines

Optimizing Your Designs for 3D Printing Success

Adhering to industry standards and leveraging design philosophies tailored for additive manufacturing can significantly enhance the performance and manufacturability of your products.

For precise guidelines on hole sizes, wall thicknesses, and other critical dimensions, download the comprehensive design guidelines sheet

General Design Philosophies for Additive Manufacturing

Material Efficiency

Less Material Usage: Take advantage of the design freedom offered by 3D printing to create lightweight structures with optimized geometries. This not only reduces material costs but also decreases the weight of the final product, which can be crucial in applications like aerospace and automotive industries.

Part Integration

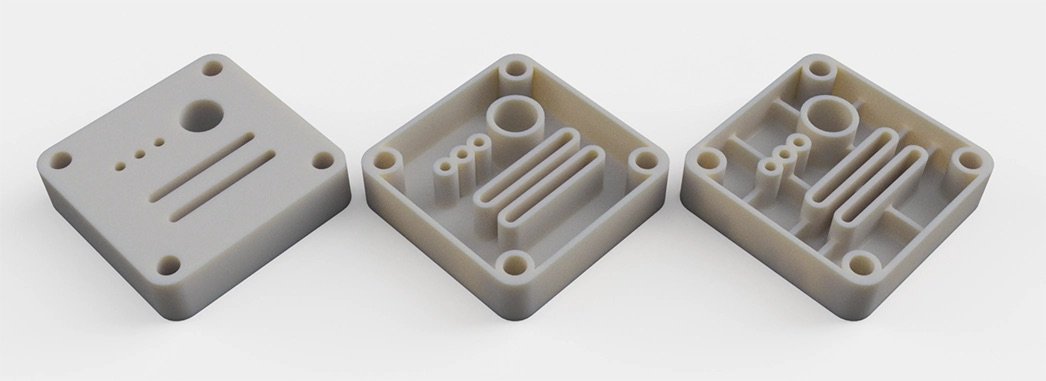

Reduce Assembly Times: Design parts to integrate multiple components into a single printed piece. This reduces the need for assembly and minimizes potential weak points caused by fasteners or adhesives.

Complex Geometries

Enhanced Functionality: Leverage the ability to print complex geometries that are impossible to achieve with traditional manufacturing methods. This can include internal channels for cooling, lattice structures for strength-to-weight optimization, and more.

Tolerances and Fits

Design for Tolerances: Ensure your design accounts for the tolerances of the 3D printing process. This is particularly important for parts that need to fit together precisely. Check Design Specification Sheet for more Information

Tailored for Powder Bed Fusion

Thermal Management

Avoid Warping: Large flat surfaces may warp during the printing process due to thermal stresses. Consider segmenting large areas or incorporating support structures to mitigate this effect.

Material Usage

Optimize Material Usage: Avoid designing large, thick sections with a lot of material. Not only does this save costs, but it also ensures better quality by reducing the risk of internal defects and making powder removal easier.

Powder Removal

Facilitate Powder Removal: Design parts with sufficient openings to allow for the easy removal of unfused powder from internal cavities. This is particularly important for intricate designs with internal channels or complex geometries.

Need Help with Your Design?

Have questions about optimizing your design for additive manufacturing? We’re here to help. Contact us today to discuss your project and get expert guidance.

Why Choose Norra AM?

-

Easy

From the moment you contact us, our streamlined processes and instant quoting system make ordering prototypes straightforward and hassle-free. We simplify the complex, so you can focus on innovation.

-

Fast

Our state-of-the-art manufacturing technology allows us to produce high-quality prototypes with rapid turnaround times. Whether you need a single prototype or a large batch, we deliver your parts quickly to keep your projects on track.

-

Local

Based in Hudiksvall, we provide personalized support and fast delivery times. Being local means we understand your needs better and can offer timely assistance and services, ensuring your prototypes meet your exact specifications.